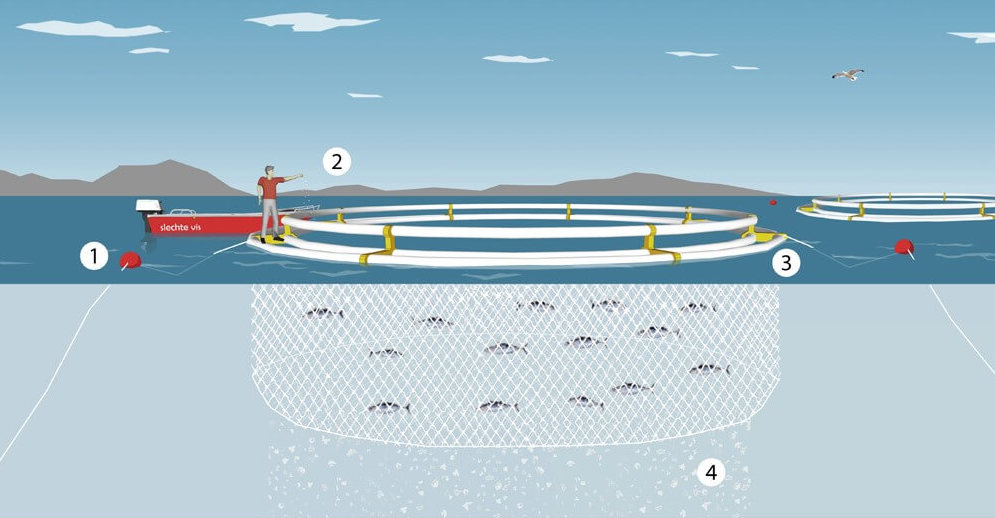

GROWING FISH IN A CAGED SYSTEM

About cage farming tilapia

1. The cage is moored to the ground. 2. Feeding with fish meal. 3. Bouyant tubes. 4. Fish feces and waste.

Site Selection and Placement of Cages

Large bodies of water tend to be more suitable for raising fish in cages than small bodies of water because the water quality is stable, the amount of water is greater, the water is deeper and richer in oxygen. In addition, the amount of waste emitted from the fish is less affected by water quality.

Cages should be placed where the water depth is appropriate and the fish net is far enough from the bottom of the body of water. In addition, the location of the cages should be planned so that they are close enough to the shore to allow proper care of the cages and fish (feeding, harvesting fish, etc.)

Special attention should be paid to the water that passes through the cages, whether it is a swift current or not, as well as the strength of the winds in the area.

Grow-Out

The optimal rate of fish growth is determined by several factors.: size of the fingerling on the stocking days, the density of the fish per square meter, the quality of the food, the quality of the water and the oxygen levels in the cage.

The use of only male populations is necessary because the growth rate of this population is 30-40% greater than the rate of female populations. This will allow faster access to the market.

Cage advantages and disadvantages

Some advantages are:

• Flexibility of management

• Ease and low cost of harvesting

• Close observation of fish feeding response and health

• Ease and economical treatment of parasites and diseases

• Relatively low capital investment compared to ponds and raceways

Some disadvantages are:

• Risk of loss from poaching or damage to cages from predators or storms

• Less tolerance of fish to poor water quality

• Dependence on nutritionally-complete diets